Working in a warehouse can be an exhilarating experience. The fast-paced environment, the thrill of efficiently managing inventory, and the satisfaction of seeing everything organized can make it an enjoyable profession. If you’re someone with a keen mind for making everything orderly, then a career in warehouse inventory management might be a perfect fit for you.

Warehouse Management: The Key to an Organized Inventory

Warehouse management is the art of overseeing the storage, tracking, and movement of inventory within a warehouse. It involves coordinating various tasks, such as receiving goods, organizing them, optimizing storage space, and ensuring timely order fulfillment. Being able to execute efficient inventory organization strategies and pay close attention to detail are essential for this important role.

According to a study conducted by the Bureau of Labor Statistics, warehouse managers play a vital role in maintaining efficient operations, ensuring customer satisfaction, and maximizing profitability. Their responsibilities include inventory control, workforce management, process improvement, and implementing technology solutions. With an average salary of $95,000 per year, this profession offers excellent earning potential and growth opportunities.

Organizing Inventory in the Warehouse: A Carefully Crafted Strategy

Organizing inventory in a warehouse is not as simple as it may seem. It requires a thoughtful approach and careful implementation to achieve success.

Determine Suitable Storage Methods

Evaluating which storage techniques are best for various product types is a crucial part of inventory management in a warehouse. This can range from using pallet racking systems to shelving units, bins, or specialized containers such as totes and dividers.

Storage Methods – Pallet Racking Systems

Create a Floor Plan

A well-thought-out floor plan can greatly enhance the organization of a warehouse. It can help you understand how best to utilize the available space and determine the most efficient routes for picking and storing items.

Implement a Systematic Approach

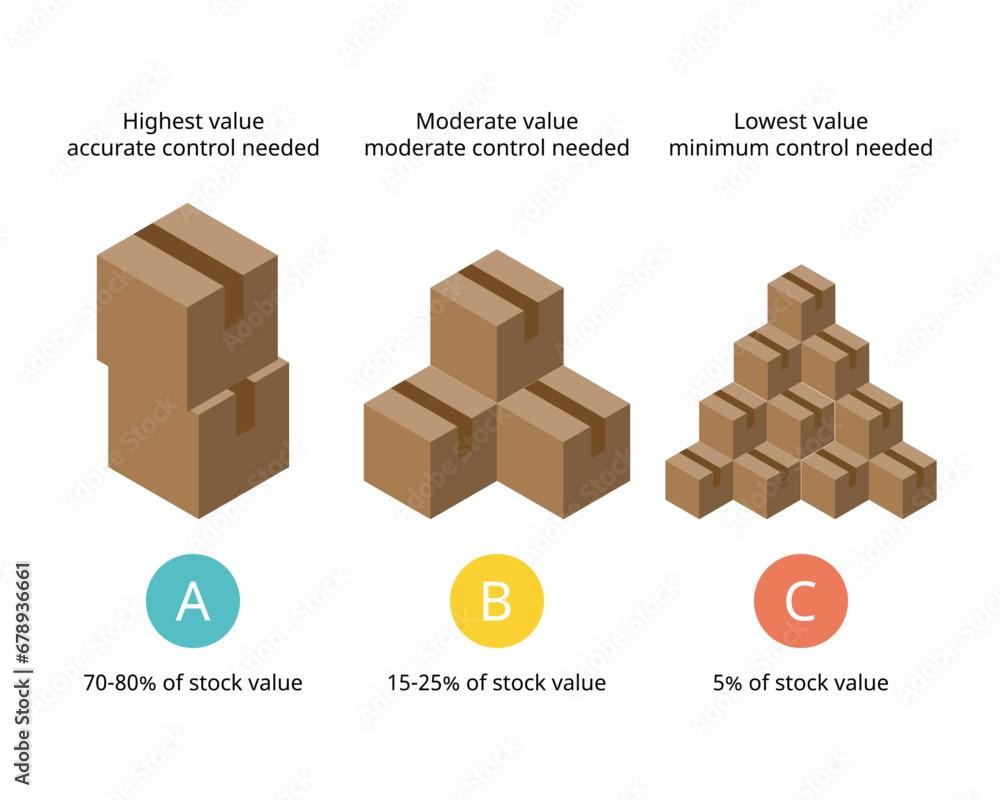

Implementing a systematic approach, like the ABC analysis technique, allows for prioritizing inventory based on its value and importance. This helps optimize storage and picking processes, ensuring that high-value items are easily accessible and managed efficiently.

ABC Analysis Technique

Use Alphabetical Storage

One of the most popular methods for arranging warehouse inventory is alphabetical storage. Keeping your storage spaces labeled is crucial to efficiency and organization.

Alphabetical Storage

Adopt Technology and Software Solutions

Adopting technology and software solutions can greatly enhance warehouse organization. Warehouse management systems (WMS) facilitate precise tracking, expedite procedures, and offer real-time visibility into inventory levels.

Warehouse technology and software solutions

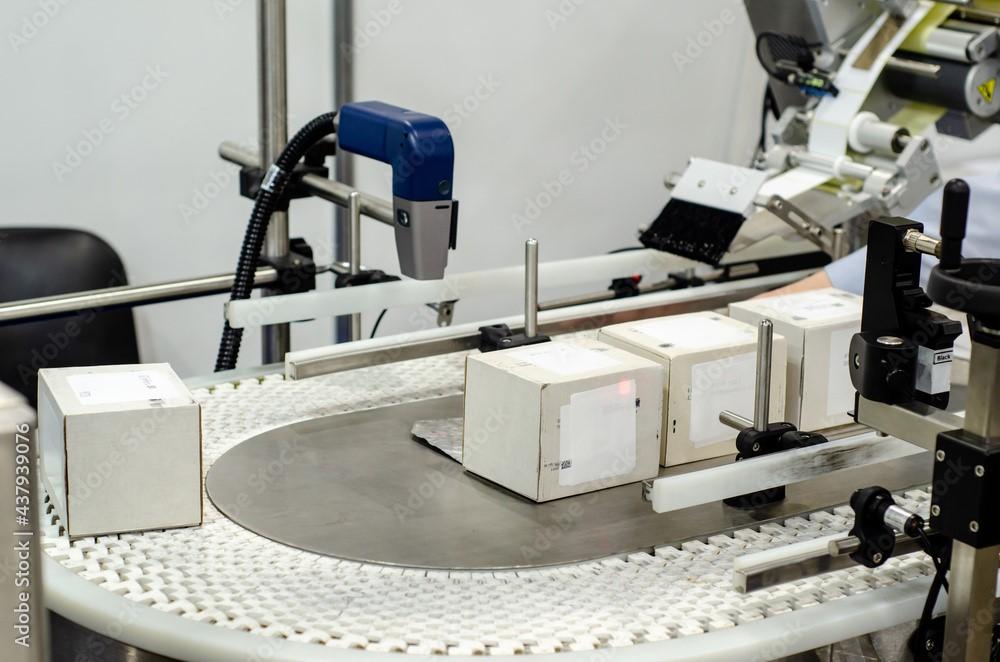

Utilize Barcode Scanning and Automation Technologies

In addition to WMS, barcode scanning and automation technologies can improve efficiency in tasks such as receiving, picking, and cycle counting. This can significantly speed up the process, reduce human error, and provide valuable data for inventory management.

Warehouse Automation Technologies

Implement a Mapping System

Maps are a useful tool for improving the organization of inventory in warehouses. Employees can rapidly determine product locations and optimal arrangements by using a map.

Maintain Regular Inventory Audits

Regular inventory audits are important for maintaining accuracy and preventing discrepancies. This could be carried out using a cycle count method, in which a small portion of the inventory in a particular location is counted on a designated day.

Utilizing Vertical Space

Maximizing vertical space in a warehouse can dramatically increase storage capacity. This involves stacking goods higher and using taller storage units. Many warehouses have high ceilings, which provide ample space for vertical expansion.

Vertical Space Storage Method

The Benefits of a Well-Organized Inventory

Maintaining a well-organized inventory in a warehouse offers numerous benefits.

Improved Operational Efficiency

A well-organized inventory can significantly improve operational efficiency. Because less time is spent looking for items, orders are fulfilled more quickly, and customer satisfaction is raised. Efficient inventory management can reduce order cycle time.

Reduced Risk of Product Damage or Loss

An organized warehouse eliminates the risk of product damage or loss. Accessible and securely stored goods are guaranteed by appropriate labeling, tracking, and storage techniques. This minimizes waste and safeguards the inventory’s value, in addition to lowering the likelihood of errors.

Effective Decision-Making

A well-organized inventory supports effective decision-making. Proactive planning and forecasting are made possible by accurate and current information on stock levels, demand trends, and order history. This aids companies in cutting carrying costs, streamlining their supply chain, and making wise choices that increase revenue.

Cost Savings

Considerable cost savings are possible with well-organized inventory management. By avoiding overstocking and understocking situations, businesses can maintain optimal inventory levels and avoid unnecessary storage and holding costs.

Improved Customer Service

Efficient inventory management also leads to improved customer service. Businesses can improve customer satisfaction and customer service by guaranteeing that products are easily accessible and orders are filled accurately and quickly.

Effective Organization is Key to Warehouse Management

Effective organization of warehouse inventory is a complex but crucial task that requires a strategic approach and constant vigilance.

Being a warehouse manager is not just about managing goods; it’s about managing space, time, and people effectively. It demands persistent skill development and exceptional organizational abilities. Warehouse managers need to keep an eye on the ever-changing dynamics of demand and supply, stay updated with the latest technologies and safety standards, and ensure seamless coordination among various activities.

The successful implementation of an organized inventory system can lead to significant cost savings, improved customer service, and a more efficient and productive warehouse operation. To achieve the best outcomes, it is crucial to keep in mind that warehouse organization is an iterative process that calls for constant observation and tweaking.

Being flexible and evolving is essential in the world of warehousing. Whether you are a seasoned warehouse manager or you are just getting started in this field, accepting change, never stopping learning, and improving your organizational skills will position you for success in this fast-paced sector. As the saying goes, “the only constant is change.”