Managing assets isn’t just about keeping them in good condition or storing them properly; it’s about strategically cutting costs and boosting your return on investment (ROI). Poorly managed assets can drag down your business, leading to inefficiencies, higher expenses, and even failure. That’s why effective asset management is crucial for business owners. According to a Deloitte study, using predictive maintenance can slash maintenance costs by up to 30%, showcasing the significant savings available through smart asset management.

To succeed, businesses should look beyond basic maintenance and develop a strategy that aligns with their goals. This involves identifying which assets are most critical, ensuring they operate efficiently, and using technology to make informed decisions.

Understanding Asset Performance Management (APM)

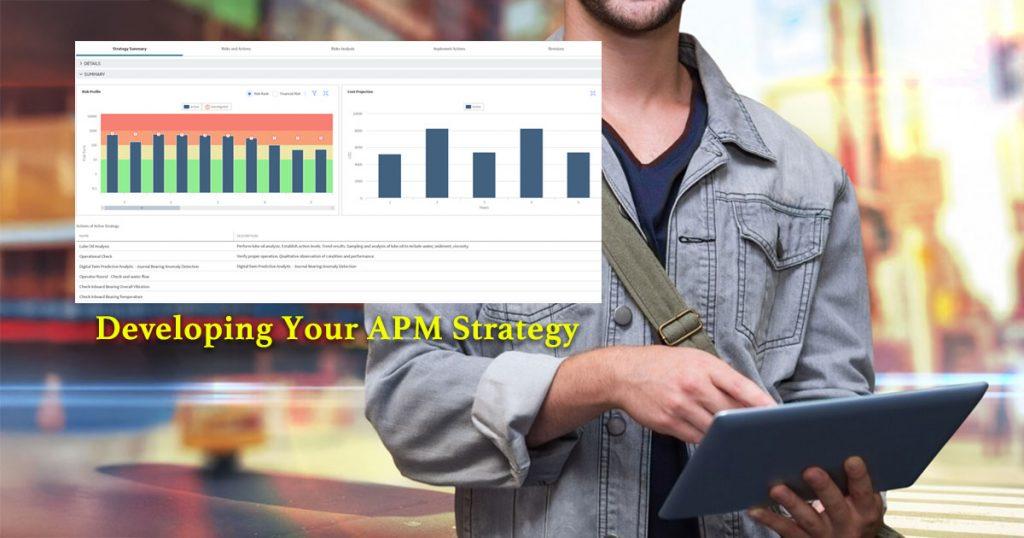

Asset Performance Management (APM) software is designed to make managing assets easier by using data analytics, predictive maintenance, and real-time monitoring. This means it helps businesses find potential problems early and plan maintenance more effectively, which reduces unexpected breakdowns and keeps equipment running longer. By predicting when maintenance is needed, companies can focus on what truly requires attention, saving both time and money.

The software combines data from different sources to give a complete picture of how assets are performing, all presented through user-friendly dashboards. These dashboards help managers quickly understand what’s happening and make informed decisions. Automated alerts signal any potential issues, allowing quick responses that minimize disruptions.

Benefits of APM Software

- APM software predicts maintenance needs to save money by allowing repairs only when necessary, thus avoiding costly downtime and unexpected repair expenses.

- It keeps assets ready by ensuring equipment is always available for use, minimizing unexpected breakdowns and enhancing productivity.

- Increasing reliability, APM software tracks asset performance to prevent unexpected failures and extend equipment life.

- The software enhances safety by identifying risks before they escalate, creating a safer work environment, particularly in high-risk industries like energy and manufacturing.

- Providing real-time insights, APM software aids in better decision-making, improving operational efficiency and resource utilization.

- Wise resource use allows APM software to prioritize maintenance efforts, ensuring they are applied where needed most, maximizing return on investment.

- Finally, APM software helps meet regulations by generating necessary reports and ensuring all equipment complies with required guidelines.

Most Effective APM Strategies for Organizations

Implementing effective Asset Performance Management (APM) strategies is key for organizations looking to optimize their operations and reduce costs, ensuring that their assets perform at their best over time.

1. Preventive Maintenance

This strategy involves setting up regular check-ups and repairs to stop equipment from failing unexpectedly. For instance, a factory might inspect its machines every month to catch any problems early. This keeps everything running smoothly, saves money, and prolongs the life of the equipment.

2. Predictive Maintenance

Through the use of data, companies can anticipate maintenance needs and avoid problems before they arise. For example, airlines might use sensors to monitor plane engines and schedule maintenance before any problems occur. This reduces surprise breakdowns and keeps costs down.

3. Asset Performance Management Solutions

These are software tools that help businesses analyze data and improve operations. For example, a power company might use this software to keep its equipment running efficiently, which improves their services and profits through better planning and decision-making.

4. Condition-Based Monitoring

This involves installing sensors on equipment to continuously check their condition and catch issues early. A chemical plant, for instance, might use vibration sensors to spot problems in pumps, allowing for quick fixes and preventing bigger, more expensive issues.

5. Lifecycle Management

Managing equipment from purchase to retirement ensures they are used effectively and costs are controlled. A delivery company might track how often vehicles need repairs to decide when to replace them, thus maximizing the value of their fleet.

6. Reliability-Centered Maintenance

Focus on maintaining the most critical equipment first to ensure reliability. For example, hospitals focus on life-support machines to prevent any risk of failure, ensuring patient safety and compliance with standards.

7. Total Productive Maintenance (TPM)

This strategy involves everyone in the company taking part in maintenance tasks to improve equipment reliability. In a factory, for instance, workers might do daily checks on their machines, catching small issues before they become big problems.

Who Benefits Most from Asset Management Performance Software

These industries can reduce costs, streamline operations, and increase asset reliability with asset management performance software, which will result in better customer satisfaction and service.

- Manufacturing companies can use this software to keep their machines running smoothly. By planning regular maintenance and checking equipment health, they can prevent unexpected breakdowns, reduce downtime, and increase productivity.

- For energy companies, the software helps keep essential equipment like turbines and transformers in good shape. It predicts when maintenance is needed, reducing the chances of power outages and making sure customers receive reliable service.

- This software helps transport companies manage their fleets better. It provides details on when vehicles need maintenance, how much fuel they use, and the best routes to take, which cuts costs and improves delivery efficiency.

- In healthcare, it’s crucial to keep equipment like MRI machines and ventilators working well. The software helps ensure timely maintenance, compliance with safety standards, and improved patient care by managing medical equipment efficiently.

- Construction firms benefit by tracking equipment use across different sites. This means machines are used effectively, maintained on time, and project delays are minimized, saving both time and money.

- Telecom companies use the software to manage networks of towers and cables. It helps monitor these assets’ health and schedule maintenance without interrupting services, ensuring customers stay connected.

- In the food sector, the software keeps production and packaging equipment working efficiently. This prevents delays, maintains product quality, and ensures compliance with health regulations.

Choosing the Right Software for Your Business Success

To wrap up, picking the best asset management performance software is vital for any business looking to improve efficiency and get the most value for their investment. The right software not only helps cut costs and keep assets running smoothly but also boosts overall productivity, setting the stage for growth. When exploring options, make sure the software fits your industry needs and future goals. Making the right decision will set your company up for success and help it maintain its lead in a crowded market. Embrace this opportunity to equip your business with the tools it needs to thrive.