Hydraulic accumulators are a fundamental part of modern hydraulic systems. First developed in the 1790s, these devices have evolved significantly over the centuries, adapting to the needs of various industries and technologies. Today, they play a crucial role in many applications, from heavy machinery and industrial equipment to automotive and aerospace systems.

Accumulator hydraulic systems offer numerous benefits, including increased system efficiency, lower operating costs, improved response time, and enhanced reliability. They also serve as a fail-safe mechanism, providing emergency power in case of system failure. According to a study by MarketsandMarkets, the global hydraulic accumulator market is projected to reach USD 784 million by 2025, reflecting their widespread use and growing demand.

What is a Hydraulic Accumulator?

At its core, a hydraulic accumulator is a critical component of a hydraulic system designed to manage and store energy. It is a pressure storage reservoir where a non-compressible hydraulic fluid is held under pressure by an external source, such as a spring, a raised weight, or a compressed gas.

The hydraulic accumulator works much like a rechargeable battery, storing hydraulic energy and releasing it as and when required. This energy is stored in the form of pressurized fluid, held ready for conversion back into mechanical force or kinetic energy. The ability to store energy and deliver it quickly upon demand makes the accumulator a vital component in many hydraulic systems.

The Role of an Accumulator in a Hydraulic System

An accumulator in a hydraulic system plays a crucial role in managing pressure differences, storing potential energy, and ensuring system stability. Here’s a deeper look at what an accumulator does and how it benefits a hydraulic system.

Energy Storage and Supply

One of the primary functions of a hydraulic accumulator is to store energy and supply it as needed. When the hydraulic system is in a low-demand phase, the pump fills the accumulator with hydraulic fluid, compressing the gas (or spring or weight, depending on the type of accumulator).

As the hydraulic fluid is forced into the accumulator, potential energy is stored. When the system requires more power than the pump can supply alone, the accumulator releases this stored energy back into the system. This process allows the hydraulic system to meet sudden or high-demand loads without requiring an excessively large pump.

Pressure Regulation

Accumulators help maintain consistent system pressure, even during fluctuations in demand. The accumulator compensates for pressure drops by releasing stored fluid into the system. Conversely, when the system pressure is too high, the accumulator absorbs the excess fluid, preventing damage to system components due to overpressure.

Shock Absorption

Hydraulic accumulators can also act as shock absorbers. They absorb pressure spikes caused by rapid changes in fluid velocity, such as those caused by sudden valve closure or pump start-up. By absorbing these shocks, accumulators protect the system’s components from damage and ensure smoother operation.

Emergency Power Source

In the event of a power failure or pump malfunction, an accumulator can provide a temporary power source. The energy stored within the accumulator can be used to operate the system for a short period until the primary power source is restored or the system can be safely shut down.

Types of Accumulators and Their Applications

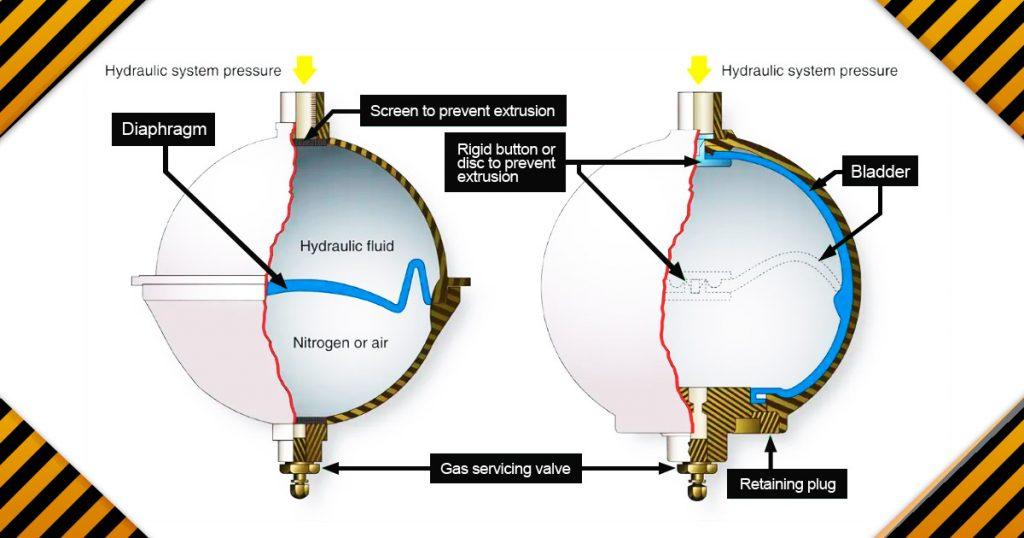

Accumulators in hydraulic systems come in various types, each with its unique features and applications. The three primary types are bladder, diaphragm, and piston accumulators. However, other less common types like metal bellows accumulators and hydraulic spring accumulators also exist. These different types are designed to meet the diverse needs of hydraulic systems.

Bladder Accumulators

Bladder accumulators are popular due to their swift response times. They comprise a fluid section and a gas section, separated by a bladder serving as a gas-proof screen. These accumulators are versatile, performing tasks such as shock absorption, pressure maintenance, and leakage compensation. Industries that require rapid response times, like aerospace and automotive, often favor bladder accumulators.

Diaphragm Accumulators

Functionally similar to bladder accumulators, diaphragm accumulators use a flexible diaphragm rather than a bladder to separate the gas and fluid sections. They are typically used in small flow rate systems and low-pressure applications due to their compact size and cost-effectiveness. Diaphragm accumulators are a great fit for mobile applications where space and weight are critical considerations.

Piston Accumulators

Piston accumulators utilize a piston to separate the gas and fluid sections. They are perfect for high-flow rates and high-pressure applications, as they can handle larger volumes of fluid compared to bladder and diaphragm accumulators. Industries with heavy-duty applications, like oil and gas or marine industries, commonly use piston accumulators.

Metal Bellows Accumulators

Metal bellows accumulators use a metal bellows to separate the fluid and gas sections. These accumulators are known for their excellent durability and resistance to harsh conditions, making them ideal for high-temperature and corrosive environments.

Hydraulic Spring Accumulators

Hydraulic spring accumulators use a spring to apply pressure to the hydraulic fluid. These accumulators are typically used in low-pressure, low-flow systems, and they’re known for their simplicity and reliability.

Primary Applications of Hydraulic Accumulators

Hydraulic accumulators are primarily used in industries where hydraulic systems are integral to operations. These industries often require systems capable of handling high-flow rates and high-pressure applications, quick response times, and reliable backup during power failures.

Industrial Machinery and Manufacturing

Hydraulic accumulators are widely used in various industrial machines and manufacturing equipment for tasks such as forging, pressing, injection moulding, and material handling. They help to maintain consistent system pressure, absorb shocks, and provide additional power when needed.

Automotive Industry

In the automotive industry, accumulators are used in hydraulic hybrid vehicles to store energy generated during braking and release it during acceleration. They also find applications in active suspension systems, improving vehicle handling and ride comfort.

Aerospace Industry

In the aerospace industry, hydraulic accumulators are used in aircraft hydraulic systems to store energy, regulate pressure, and provide an emergency power source. They are crucial in operating landing gear, brakes, flight control surfaces, and other hydraulic-powered components.

Energy Industry

In the energy sector, accumulators are used in wind turbines to regulate the hydraulic fluid’s pressure used in the pitch control system. They are also used in oil and gas drilling and production operations to handle high-pressure applications.

Construction and Mining Equipment

Hydraulic accumulators are integral to many construction and mining machines, such as excavators, loaders, and dump trucks. They help to smooth out pulsations, absorb shocks, and provide extra power for lifting heavy loads.

In essence, the applications of hydraulic accumulators are vast and varied, reflecting their vital role in many industries. As technology advances and hydraulic systems continue to evolve, the importance and versatility of hydraulic accumulators are set to increase even further.